ENTAG is an advanced solution in complete management of industrial costs & production (ERP) in order to have full organization of all industrial facilities processes concerning costs management

It’s one of INFOCUS-MIS’ ERP systems & the fruits of efforts since 1997 & beyond of continuous experience in different management information systems

Applying management systems of production costs varies from facility to another due to difference in the industry or nature of provided products that the facility provide, or even the mindset of facility’s top management and different points of opinion in observation and analysis

Thus, IFNOCUS has come up with ENTAG, the comprehensive system for management of industrial costs management which features a great level of flexibility making it able to cover almost all types of industries

This system works on most powerful ORACLE databases in the market, it’s concerned with management of basic & essential factors that control the lifecycle of the production process in terms of planning, production, following-up, monitoring, matching, analysis and decision-making information

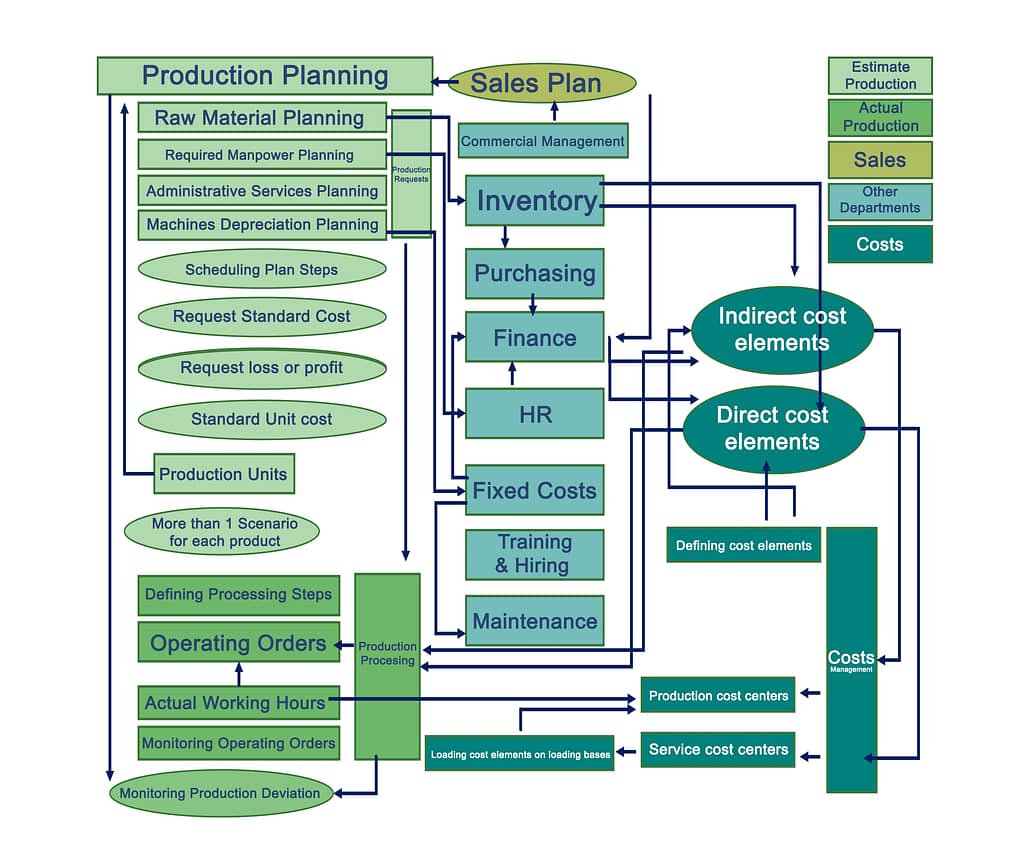

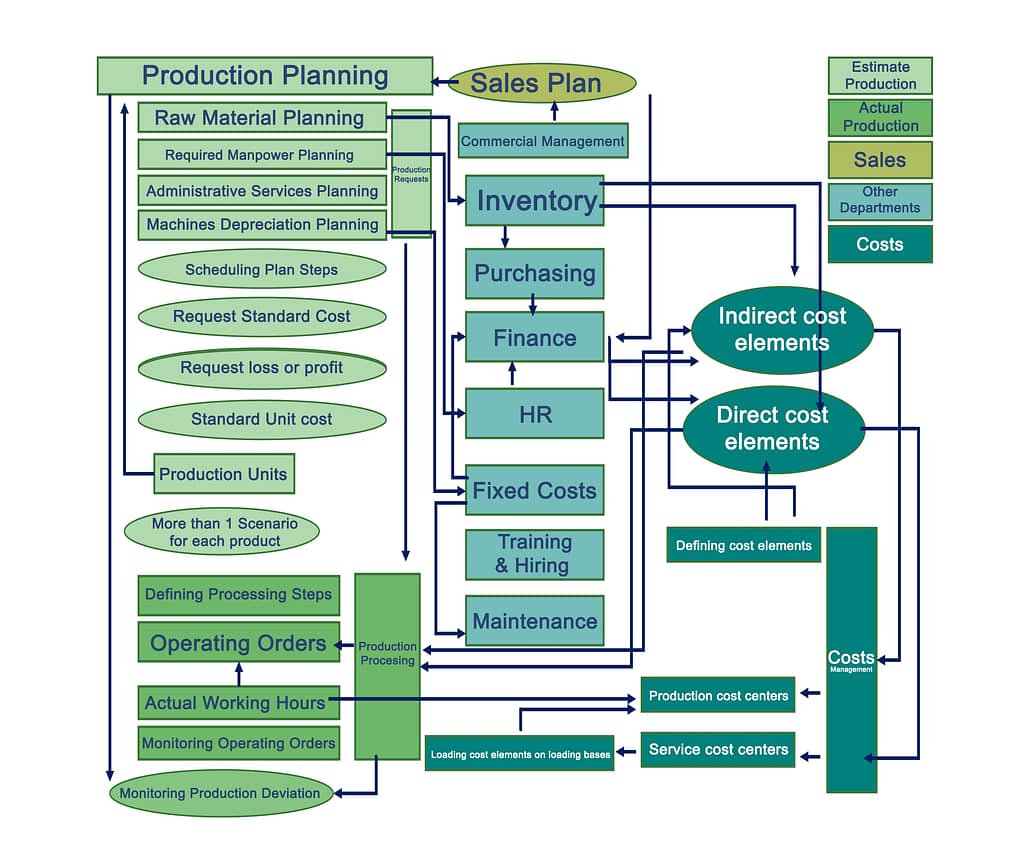

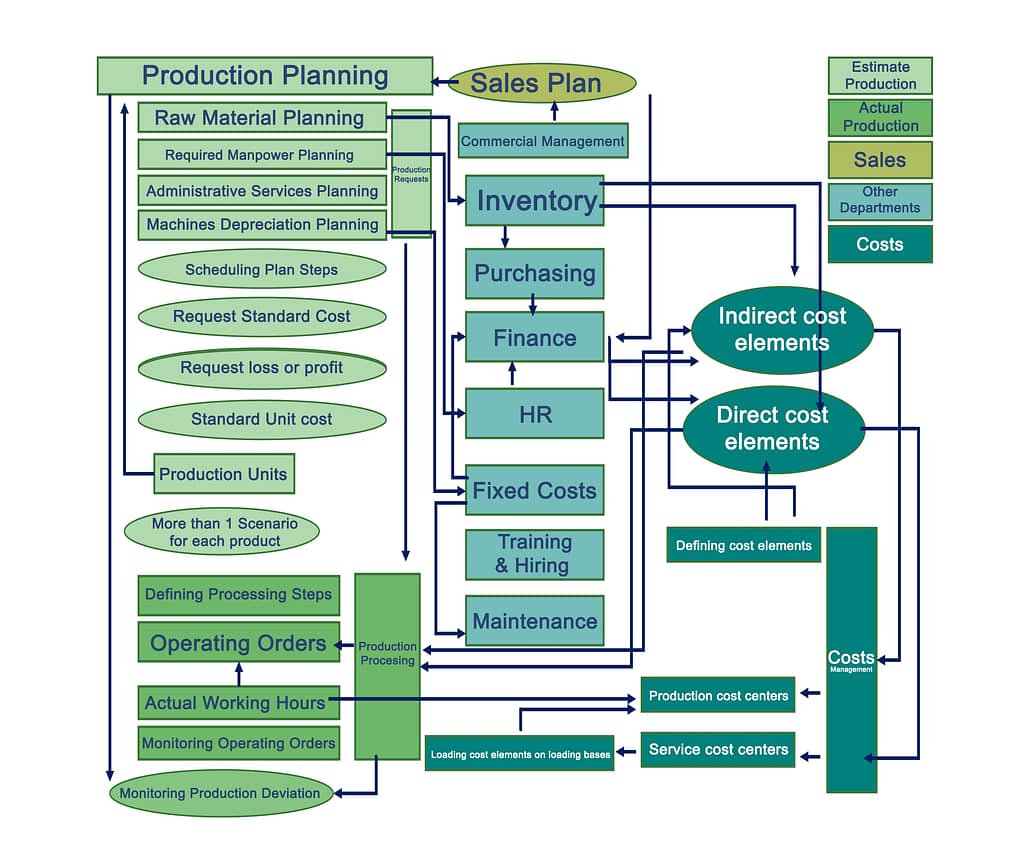

Production Planning

Products specifications are very vital role in this system, the user can be using this feature to have estimate costs before the production process and generate an approximate schedule for the production time

This part of the system contains many elements that can be used according to user’s preferences, such as standard costs of materials and expenses, chart of production hours for people and machines, and the scheduled timetable for execution and quality standards… and many other options

You’re able to calculate estimated budget for cost components, also the system can make comparisons and deviations of estimations and former actual results

The system also features the ability to calculate estimated production volume distributed on specific time periods, and compare between estimated & actual production volume

Production Processing

ENTAG’s system features complete capability of controlling all elements of cost elements tree as the user can define types of cost elements in the way mathcing the facility’s work cycle, in addition, the user can add unlimited number of cost elements and classify it

The system offers great flexibility in dealing with analytical tables of cost elements tree in suitable manner for the facility as well as enormous flexibility in dealing with changing degrees that allows displaying changing costs and fixed costs among each element

You can have full control over cost centers tree as you can define types of centers and nature of each one, in addition to defining centers with ability to reload on other centers and having reloading from other centers, which consequently gives many capabilities of dealing with these centers

In addition, the user can enter statistical data for each center individually, also can distribute total cost on cost centers or distribute a single element or more, as well as the ability to re-distribute based on percentages or statistical chart

The user can also arrange loading on cost centers as he/she can distribute or re-distribute based on the recommended arrangement

All of these features empower the user with priceless flexibility in dealing with production cost centers

Concerning production processing, this system has the ability to define all types and categories of processing steps, in addition to defining different tasks in each processing step, connecting every task with its schedule, calculating time interference of processing steps, and extracting the acutal processing time

As well as monitoring and observation of estimated and actual production power for machines and manpower over different steps, also monitoring depreciation of every cost center and every processing step

The system features full control over operating orders where you can categorize them based on their nature, connect them with sales department requests, monitoring operating steps and the scheduled time plan for each, monitoring movements of cost elements regarding materials and expenses, monitoring production hours and service hours for each operating order individually

In addition, you can monitor cost of each operating order in every processing step, and extract the cost of each order as well as many other features ENTAG system provided concerning operating orders

Monitoring day-by-day movements of cost elements is very vital for any industrial facility. Thus, this system provided many important features such as monitoring expensed materials on each operating order and cost center, and following-up with each processing steps

Also monitoring expensed costs on each operating order and cost center, and monitoring production hours on each cost center